Achieve the highest value of assets and minimize risk and cost

How do they reduce risk and optimize asset performance while keeping maintenance costs low?

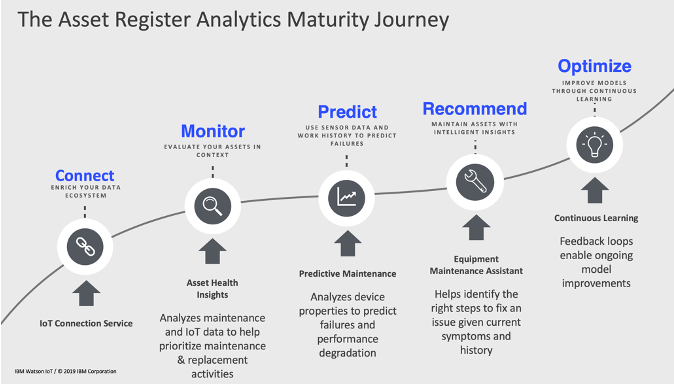

Many solutions are either in the area of Work Order Management (EAM) or Strategic Asset Maintenance Plan (SAMP), like time-based maintenance or usage-based maintenance. The move forward to condition-based and ultimately predictive and prescriptive maintenance is often a huge leap to take.

Being focused on the ISO 55000 standard and delivering industry solutions for Asset Management the need for Asset Performance Management (APM) is evident.

Asset Performance Management identifies the real asset health

Asset Performance Management (APM) enhances your Enterprise Asset Management (EAM) foundation, using AI, advanced analytics and real-time data from sensors and devices to help propel your business forward.

Key capabilities of APM

- Optimize asset health when you understand your equipment’s needs

- Predict asset failure and avoid surprises

- Extend the useful life of assets

- Prioritize repairs and replacements

- Improve asset strategy and asset management processes

IOT and SONORS, really necessary?

Gathering and using data by using IoT and sensors often is a bridge too far. We introduced a new definition the principle of the “X of things”; enabling every organization to benefit at the earliest.

- HSoT: Human Sensor of things – just execute human observations or inspections and enter the observed measurements by using inspections;

- EoT: Ethernet of Things – connect your EAM system to Scada or PLC systems;

- IoT: Internet of Things – if more relevant asset information is required and replace the human measurement observations by sensor data not available via Scada / PLC, then use IoT sensors to get this data.

Asset Performance Maintenance key benefits

- Reduce unplanned downtime and risks Predict asset failure and initiate actions to avoid breakdowns;

- Reduce maintenance costs Avoid over-maintained assets by enabling scheduled maintenance before failure based on early warnings;

- Improve asset utilization Enable more efficient assets when you can predict maintenance issues and reduce failures on the job;

- Extend asset life Identify operational factors and improve maintenance practices and reliability

- Increase production output Helps make industrial manufacturing, production, processes and products more efficient and dependable to deliver higher output.